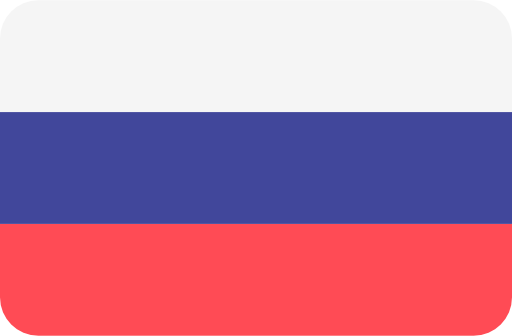

LISA Series Cooling Tower

Code : 104

It is a CTI-Eurovent certified open circuit cooling tower model.

It is manufactured with the most current design criteria in order to maximize the cooling capacity of the tower. It is mainly used in the HVAC industry and where cold water is needed.

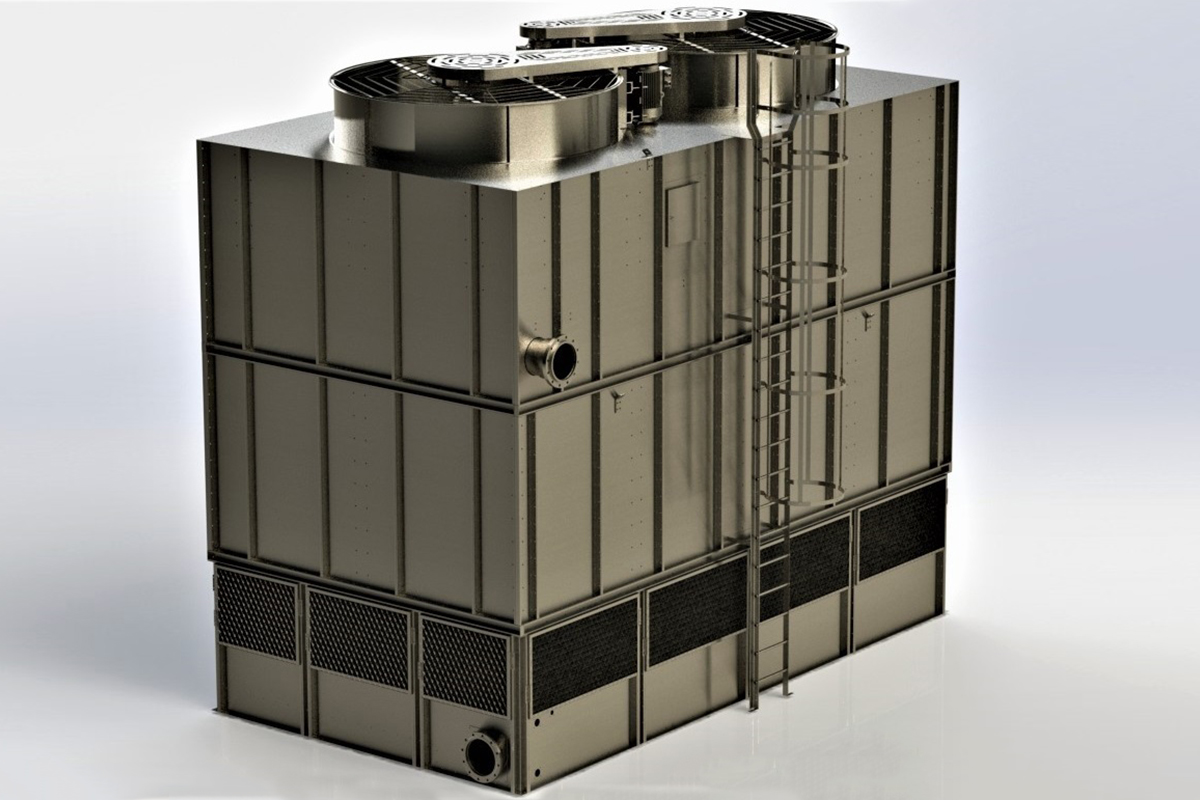

This type of towers are designed with the counter flow water cooling principle. Hot water is poured over the cooler fill while air passes under the cooler fill with this design criterion. During the process, the hot water provides heat transfer through the air and the cooler fill. When it leaves the filling, the cold water is stored in the pool and sent to the required part when needed.

The fan is designed as top-suction. For this reason, axial fans are located on the deck of the tower. We also have applications with belt pulleys or reductors, depending on the request of the customers.

Optional Equipment

- Optional equipment for all our models is listed below;

- Quiet and ultra-silent fans

- Automation system

- Electric panel

- Double speed fan engines

- Water filtration system

- Chemical dosing system

- Electronic water level controllers

- Low water level switch

- Electric pool heaters (Resistance)

Main Structure, Body and Tower Pool

Z600 (600 gr/m2 zinc coated) galvanized steel is used as standard. Thanks to Z600 Galvanized Steel, the towers are durable and corrosion resistant.

Alternatively, Stainless Steel is also used.

Coolant Filling

The fill consists of corrugated PVC labels that are hot formed and joined together in modules and occupies its entire area. Film type fillings are vacuumed to provide maximum cooling surface and minimum air resistance.

After the water is sprayed on the upper surface of the filling, it gives its heat to the air that is moving in the opposite direction while it flows down in the form of a thin film layer on the filling.

This heat exchange occurs due to evaporation. The height and elevation of the fill are chosen to provide optimum air distribution and heat transfer. The plastic material that makes up the PVC film is suitable for working at temperatures between -5 C and +55 C and does not cause any deformation or permanent damage. Different materials could also be used for different temperature ranges.

Fan Group

Fan blades are designed to provide silent operation. Blade angles could be adjusted manually when the fan is stationary. It is possible to easily mount the blades to the fan hub with U-bolts. Fan blades are produced with aluminum extrusion. In all our models, direct coupled engines and gear units with direct coupled engines are used in IP 55 protection class, insulation class F, heat increase class B, operating at 3-phase 50 Hz or 60 Hz frequency values. In this way, the risk of belt breakage in belt-pulley driven engines is prevented.

Water Distribution System

One of the most important elements of thermal performance is the optimum water distribution system. Our company conducted extensive research for this purpose.

The water distribution system consists of PVC main collector and PVC secondary pipes in the designed tower and is designed to wet the entire surface of the coil. The spray nozzles are made of glass fiber reinforced polyamide material and have high resistance to all kinds of chemicals and low clogging risk. They could be mounted on the PVC pipe without any extra materials. Nozzles also could be disassembled and mounted by hand without any tools.

Drop Holders

Sinusoidal wave type profile eliminators made of PVC material hold the water droplets in the discharged air. Thus, the water circulation losses at the design point can be reduced to 0.00%.