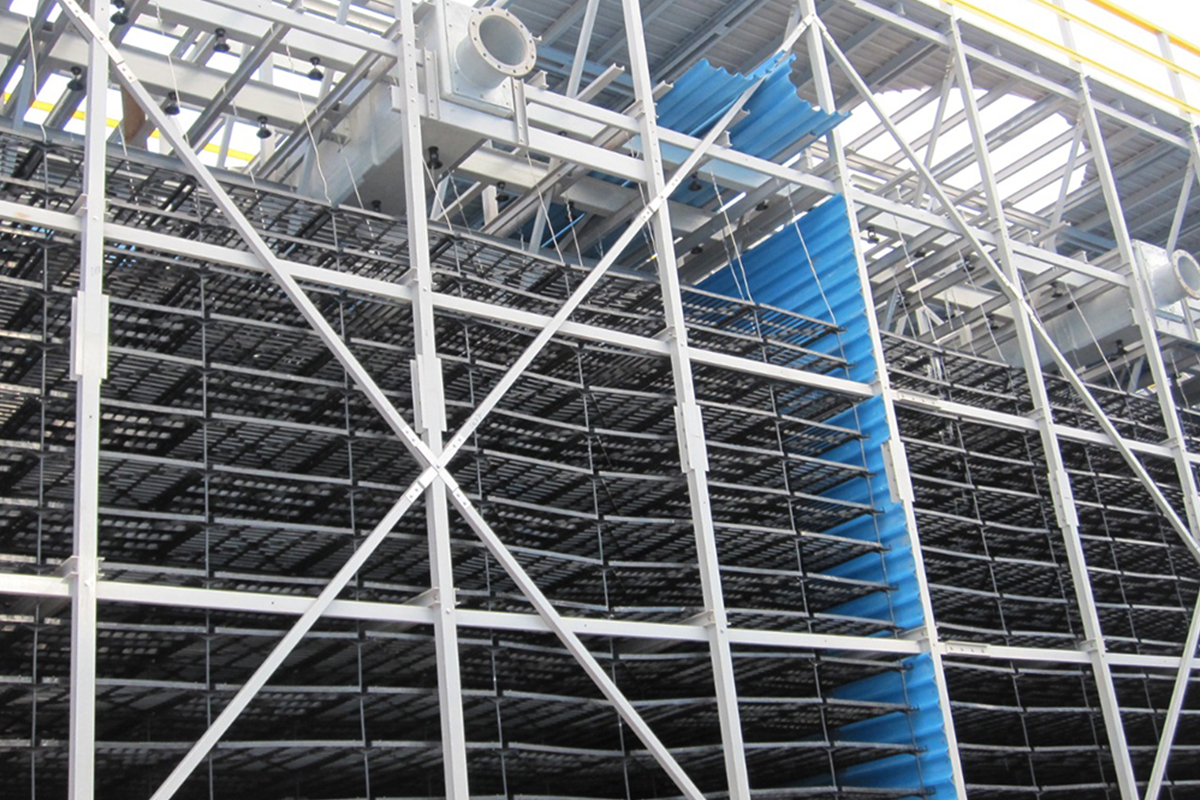

Splash Fill

In the grid type filling, cooling is supported with the effect of splashing. This type of filling is especially preferred for polluted waters. The grid filler plates are applied in a staggered way for the best polarization of the water. The distance between the infill layers is important as it affects the following:

- Minimal clogging

- Self cleaning

- Thermal performance that does not decrease over time

During the downward flow of the water process, it hits the fill layers and breaks up into smaller drops. This division is repeated in each layer of infill with the formation of more and smaller drops reaching the maximum amount of heat transfer surface where cooling takes place.

Each grid filler plate is fixed in place with star distributors. These star distributors are also fixed to vertically suspended stainless steel wires. Each plate could be easily disassembled and replaced without damaging other parts during disassembly. This feature makes access easier to every part of the tower for maintenance or inspection purposes.

The wide distance between the filler plates prevents clogging and the accumulation of biological formations. The design and arrangement of the filling requires a long and comprehensive research and devoted work. The grid table filling system has been used successfully all over the world for more than 10 years. Our company has continuous product development studies at our facilities In order to provide the highest heat transfer and the lowest air resistance with the grid plate filling.